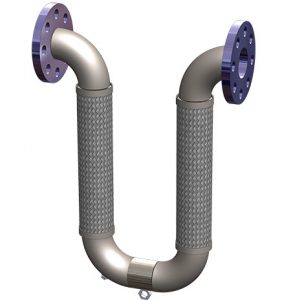

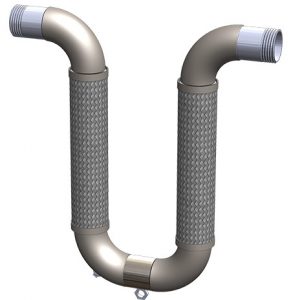

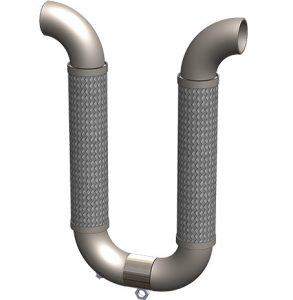

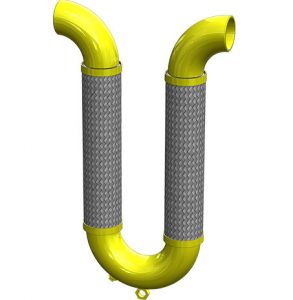

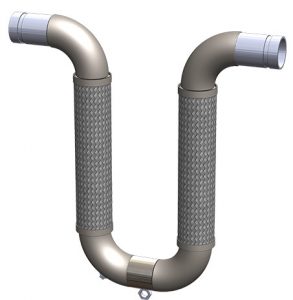

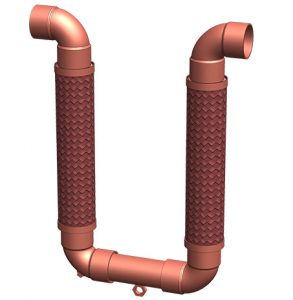

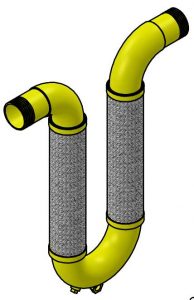

"U" Loops

Seismic & Thermal Motion

Unlike large pipe loops, “U” Loops take up a minimum of space, providing pipe motion accommodation solutions in limited space situations such as indoor piping. The small configuration of the “U” Loops are also far less susceptible to the heat loss that must be dealt with in the case of large pipe loops.

Whereas metal bellows or rubber expansion joints will impose substantial anchor loads due to the effects of static pressure thrust, “U” Loops will not introduce any thrust loads on the piping system. The unique construction of the braided U-shaped loop creates a flexible product that does not expand when pressurized. A welded-on braid acts as a restraining device, even at extended pressures, yet allows tremendous flexibility. Anchor loads in regard to the “U” Loops are confined to the relatively small spring forces required to deflect the flexible legs within the loop. Unlike expansion joints, a minimum of pipe guiding is required.

The standard position for the “U” Loop is in a horizontal pipe run, with the elbow pointing straight down. Positioning is versatile, however, and the loops can be installed in many other positions such as laying the loop horizontal, positioning the elbow straight up, or positioning for vertical pipe run. In installation other than the standard position, EFP can provide a support eyelet to allow a cable or rod to support the weight of the loop and its contents.

“U” Loops can be used for a variety of fluids and gases. Loops can be constructed using stainless steel hose and braid with carbon steel end fittings and elbows, or with bronze hose and braid with copper end fittings and elbows. End fitting options include flanges, male threads, beveled weld ends, grooved ends, and copper sweat.

Standard “U” Loops are offered for either 2″, 3″, or 4″ of motion from center-line in axial and offset planes. Loops for even greater motions can be constructed upon request.

Seismic & Thermal Pipe Motion

Specified by consulting engineers and building owners and installed by contractors for many years, “U” Loops solve the problems of pipe motion caused by thermal pipe growth and the unpredictable movements associated with seismic activity. “U” Loops can perform the functions of large pipe loops or expansion joints, and in addition, can provide protection and flexibility in multiple planes during potentially catastrophic earthquakes.