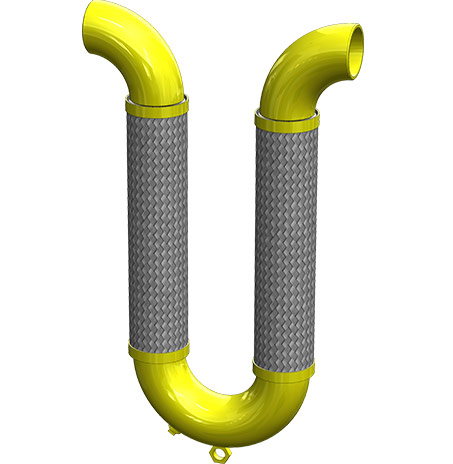

U Loops CSA Weld Ends

Downloadable PDF: U Loops CSA Weld Ends

Home » U-Loops CSA Weld End

Hose:

Series 300 Stainless

Braid:

Series 300 Stainless

End Fitting:

Sch40 Weldends

Fitting Material:

Sch40 Carbon Steel or Sch40 Stainless

| U Loops CSA Weld Ends | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size NPS | Axial Movement | A (IN) | B (IN) | Working Pressure (PSIG) | |||

| 1/2" | ± 4" | 15 | 18 | 150 @ 70°F | |||

| 3/4" | ± 4" | 16 | 20 | 150 @ 70°F | |||

| 1" | ± 4" | 16 | 22 | 150 @ 70°F | |||

| 1-1/4" | ± 4" | 16-3/4 | 22 | 150 @ 70°F | |||

| 1-1/2" | ± 4" | 17-1/2 | 23 | 150 @ 70°F | |||

| 2" | ± 4" | 14 | 25 | 150 @ 70°F | |||

| 2-1/2" | ± 4" | 15-1/2 | 26 | 150 @ 70°F | |||

| 3" | ± 4" | 18 | 29 | 150 @ 70°F | |||

| 4 | ± 4" | 24 | 37 | 150 @ 70°F | |||

SPRING FORCE:

*These values reflect the total force required to move the U-Loop it’s full rated movement for 150 PSI @ 70°F. All dimensions are in inches.

U Loops CSA Weld Ends

NOTES:

There is no “standard” hanging orientation for loops as illustrated. Up, down, sideways; these are all acceptable. If steam is the media for the application, loops should be double braided regardless the working pressure. The orientation for steam loops should be considered in such a way to avoid condensate build up. Shipping bars are included with all loops.

NSF 372 – LEAD FREE: The wetted surface of this product contacted by water contains less than one quarter of one percent (0.25%) of lead by weight. Material complies with state codes and standards where applicable, requiring reduced lead content.

U-Loops 2″ and larger installed in any orientation other than hanging down MUST have the return supported. (See installation instructions.)

Custom configurations available to suite your needs